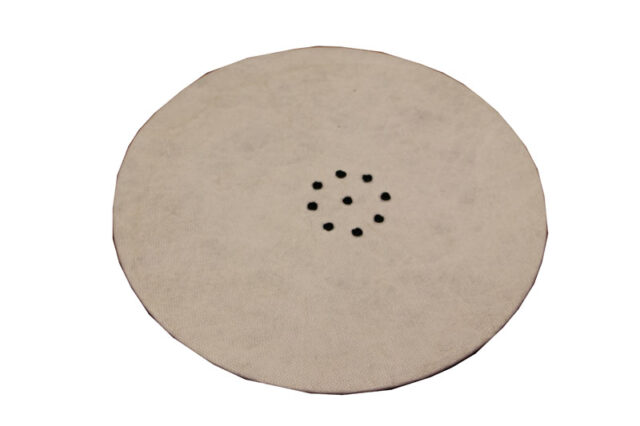

When using suction cups, impressions tend to be left on the glass. This is a problem, especially on coated panes of glass. If you believe the advertising messages, avoiding these impressions is generally considered to be an easy matter. All you have to do is to use MTC covers on the suction cups, and hey presto – these dirty marks simply vainish.

The promotional messages about this product refer to a reduction in friction coefficient. Have you also given some thought to using these covers on your suction cups? The product description quotes a figure of a few percent in relation to horizontal applications. When does that actually occur in a glass processing operation? And did you know, as university investigations have demonstrated to us, that this load scenario ceases to apply at an inclined angle of ust 10° from the horizontal? In vertical applications, the manufacturer refers to a reduction of about 50% when these suction plate covers are fitted.

Since glass is almost always transported in a perpendicular position, and if you pay attention to these figures from the manufacturer, you need to have double the number of suction cups to achieve the same carrying capacity or, in other words, your device is then only able to lift half of its rated load.

- If you have paid attention to these figures, are you sure that you are erring on the safe side?

- Can you work without any danger at all in this way?

- Or is there more to which you should pay attention?

You need to know the answer to that!

Our obligation to monitor products has compelled us to take a closer look at this application, and to test the impact on that application of our vacuum lifters when the suction cups are fitted with MTC covers.

In 2003, the technical university was once again assigned this task. We then published the test results on our website, and included related notes in our operating manuals.

Anyone wishing to consult this can go to the following link, showing the test results at that time obtained by the Technical University in Kiel on the behaviour of suction cups with a pulp cover.

Betriebsverhalten von Saugern mit Zellstoffüberzug

The result of this test shows that only about 25% of carrying capacity is retained.

You therefore lose 75% of the original carrying capacity.

In 2015 we conducted a test using our own test fixture to check this result once again for ourselves. The people we spoke to kept expressing doubts about those initial results.

In our test, the normal new 388 suction cup achieved a carrying capacity of 259 kg, reduced to 72 kg when a new MTC suction plate cover was fitted.

By way of comparison, a copy of the 388 suction cup made by Eurotech was tested, under the same conditions as the 388 suction cup made by Pannkoke. For a short period, this suction cup was also able to hold a load weighing more than 200 kg, but this then dropped to approx. 110 kg. And please note: this result was obtained without an MTC suction plate cover being fitted. This insight should also be borne in mind whenever suction cups are replaced. Not every suction cup of the same size has the same carrying capacity.

Then the test was conducted with the MTC suction plate cover. Here, once again, only a load of approx. 70 kg could be held.

This means that if you take the poor figure for the suction cup made by Eurotech, the reduction amounts to 37%. This leaves a carrying capacity of approx. 63%. If you take the figure for the 388 suction cup made by Pannkoke, the carrying capacity drops to 28%.

We have made a short video showing the highlights of this test which you can find on our YouTube channel. There, you can see a further set of problems associated with the use of MTC suction plate covers. Your vacuum system starts to leak causing a loss of vacuum that leads to a further loss of carrying capacity. If your vacuum supply fails, the situation becomes even more dangerous. This diminishes the level of safety built into your vacuum lifting device.

Here is the link to that video: How do suction cups with covers behave to protect coated glass panes?

Find this on YouTube

We were not simply content with that, and conducted yet another test as part of our preparations for the 2017 safety training course. Once again, a 388 suction cup with MTC suction plate cover was tested. The outcome on that occasion was a carrying capacity of 20 kg. This test established that no vacuum at all was being generated after initial suction had been applied. We therefore simulated a power failure simuliert and, about 4 minutes later, the suction cup was only able to hold a load of 20 kg! In this test, the chronological sequence was recorded at the same time.

Here is the link to that video:

Find this on YouTube

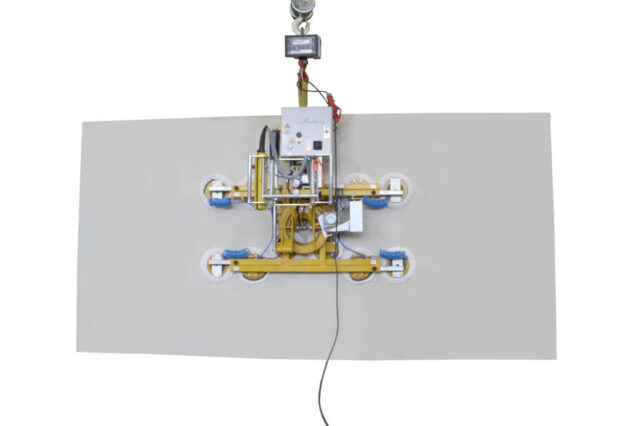

If you are not already convinced that these suction plate cover constitute a major risk, here is yet another example: in 2019 we a vacuum lifting device was returned to us for conversion. The Kombi 7031-DmS-07 vacuum lifter was manufactured in 2017 and was to be retrofitted with a motorised rotational drive. A load test was performed prior to delivery.

The outcome: the test with the MTC suction plate covers ran as expected, and the device slipped across the steel plate when the load rating reached 556 kg.

The outcome: without the MTC suction plate cover, the steel plate was still able to hold a load weighing 2007 kg.

Once again, a huge reduction in the carrying capacity of the device was confirmed. Only about 27% of the original carrying capacity was achieved. Furthermore, the vacuum system started leaking when the MTC suction plate covers were used.

Unfortunately, there is no other way of avoiding the impressions (marks) left on the surface by contact from the suction cups.

Be aware of the risk that you take when using these covers.

Our advice

- Assume a reduction in carrying capacity of 75%.

- Use correspondingly more suction cups to obtain a sufficient safety margin

- Always bear in mind that, normally, a vacuum lifter should always be able to carry loads weighing double its design rating. In other words, always aim to operate within a safety factor of 2. The values obtained should therefore always be divided by 2.

- Pay attention to ensuring that the vacuum supply must not be allowed to fail.

If this does happen, move yourself to a safe location because carrying capacity will continue to decline.

Only use these MTC suction plate covers if you absolutely have to.

Your personal safety and that of your payroll staff is at stake!

To prevent disaster from striking, give careful thought to why you are still using equipment in this way. Keep a written record of your considerations. We most certainly advise you against a policy of ”if it ain’t broke, don’t fix it”. In our view, using these MTC suction plate covers is hazardous – it should not become a habit to use them without careful reflection.