Carrying capacity of suction cups when using a woodpulp cover for the protection of the coating

of coated glass

Executed with suction cup 388 of Pannkoke and Euro-Tech

An investigation by the University for Applied Science in Kiel

(executed in the first six months of the year 2003)

conducted by Professor Dr.-Ing. Michael Klausner

In general

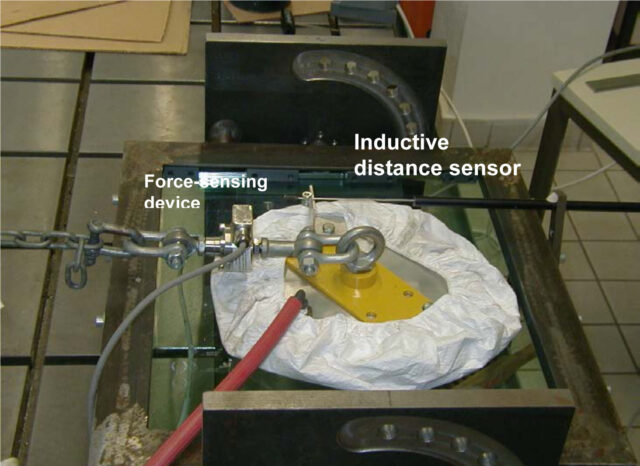

The suction cups Euro-Tech-388 and Pannkoke-388-1998 were investigated with a woodpulp cover for gliding off (= pulling direction parallelly to the glass surface). The trials were conducted on the same test equipment as previous trials series ( ) (see picture 1), as static trials. Performing a dynamic trial till a tear off does not make sense because already clearly under the tear-off limit of the suction cup the holding force leads to a creeping of the suction cup. This can be perhaps accepted to a certain extent in practical operation.

Execution of the trial

The suction cup Euro-Tech-388 was tested first( ) (see picture 2). The load was brought on statically and increased in steps until a clear creeping motion started, then followed a load alleviation through which the creeping came to a stillstand. Once more the load was again increased till creeping. The vacuum was always at – 0.6 bar.

The following table indicates the gliding speeds which were measured at different load steps:

| Force [N] | Time for 1 mm creeping distance [s] | Comment | Force [N] | Time for 1 mm creeping distance [s] | Comment |

| 550 | 105 | 550 | >480 | Standstill | |

| 514 | >480 | Standstill | 528 | 120 | |

| 545 | 480 | 557 | 330 | ||

| 507 | >480 | Standstill | 478 | >480 | Standstill |

| 546 | 480 | 414 | >480 | Standstill | |

| 538 | >480 | Standstill | 511 | 240 | |

| 490 | >480 | Standstill | 551 | >480 | Standstill |

Table 1: Creeping of the suction cup Euro-Tech-388

The creeping speeds spread clearly but the value of 511 N could be taken as the limiting value because a creeping of 0.25 mm/min seems to be tolerable in consideration of usual lifting and mounting times and on the other hand was registered mainly for this force as a quasi stillstand (creeping speed < 0.17 mm/min).

At a second trial the suction cup Pannkoke-388-1998 was tested with the same woodpulp cover and with the same vacuum. The following table indicates the measuring results:

| Force [N] | Time for 1 mm creeping distance [s] | Comment | Force [N] | Time for 1 mm creeping distance [s] | Comment |

| 685 | >480 | 739 | >480 | ||

| 705 | >480 | Standstill | 758 | >480 | |

| 736 | >480 | Standstill | 801 | 240 |

Table 2: Creeping of the suction cup Pannkoke-388-1998

Results

The Pannkoke suction cup can still take a load of 758 N at a creeping speed of <0.17 mm/min with this result and has therefore a 48% higher carrying capacity than the nearly surface equal Euro-Tech suction cup. Due to the fact that the same woodpulp cover was used for both trials and at the Euro-Tech trial no coefficient of friction was observed, the higher carrying capacity must be attributed to the special profil of the suction cups’ underside.

The use of the woodpulp cover leads to a drastic decrease in the carrying capacity and furthermore the vacuum system will be untight because of the cover and loses vacuum which leads, without pumping, to a loss of vacuum and therefore to a loss of the carrying capacity.

For comparison, a Pannkoke 388-1998 can carry, without a woodpulp cover, a tension force of approx. 3120 N and with a woodpulp cover only a tension force of 758 N. When the required safety factor 2 is taken into account, the carrying capacity with a woodpulp cover is approx. 38 kg and without a woodpulp cover approx. 150 kg.

Whereas if the product of Messrs. Euro-Tech is used the carrying capacity reduces at a 2-fold safety factor to approx. 26 kg.