This also has to be tested during maintenance work!

Operating Manual

Part of any complete vacuum lifting device (and the same is true of all other devices / machines) has to be an operating manual in the national language of the user.

Which requirements, among other things, does the operating manual have to satisfy for the device to comply with EU standard EN 13155?

In Section 7.1.1 generally calls for examples:

- a short description

- the carrying capacity

- the instructions for application / use

- handling and storage

Section 7.1.2.2 still has a few requirements for the vacuum lifting device. These include:

- checking the vacuum

- what needs to be done if the warning equipment is triggered

- how to test connections and hoses

- how to test the condition of the suction plate

- what holding time the device has in the event of a power failure.

The operating manual also contains maintenance instructions for the vacuum lifting device. This is defined more precisely by Point 7.1.3.

- a repair manual

- the use of only genuine parts

- a list of components

Section 7.1.4. also requires a test and inspection of the vacuum lifting device. Among other things, information is required here for the following points:

- prior to initial operation

- service life.

On unknown devices an approximate test should be conducted to establish if the operating manual covers the topics in this area that enable the device to be assessed as safe.

In the absence of an operating manual, the device is not safe. The same applies if the language does not match that of the country in which the device is being used.

This is therefore very important when purchasing previously owned devices.

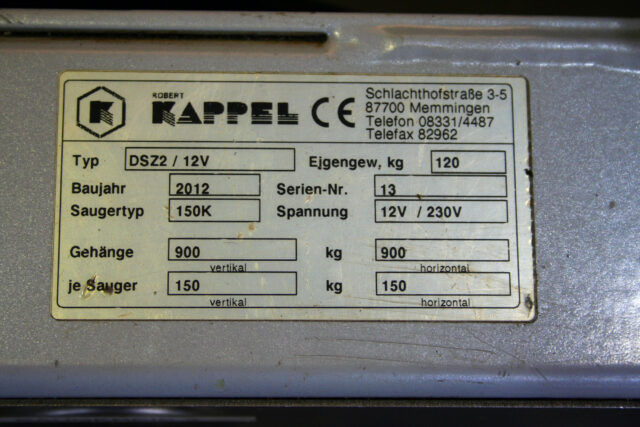

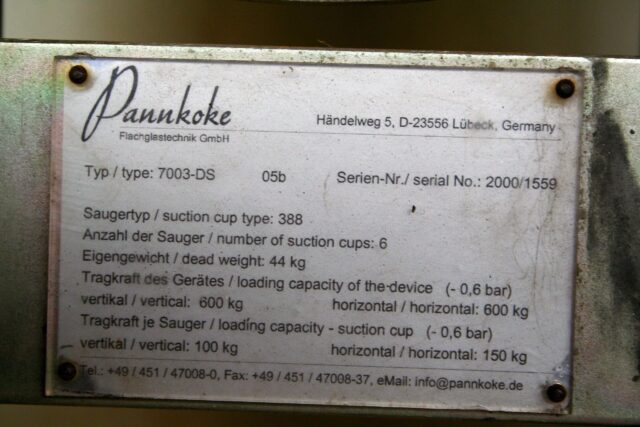

Rating plate & Co.

In the absence of identification, or with only partial identification, a device is deemed to be unsafe even it appears to be functioning perfectly well. In such cases, during maintenance work, all functions should be tested.

It is very important to know, and this applies to all workplace equipment, including items manufactured on site. Every recently built device with a CE mark needs to have a rating plate, an operating manual in the national language of the user and a conformity declaration. If any one of these is not available, the device is not safe and is not entitled to have a CE mark.

The following minimum requirements apply, as defined in Point 7.2 of EU standard EN 13155:

- The company name with the complete address of the manufacturer in the EU or the manufacturer who imported the device / machine into the EU. The address of a manufacturer outside the EU is not sufficient here.

- The designation of the device / the machine

- The serial no. of the device / the machine

- The dead weight of the device / the machine

- The build year of the device / the machine, i.e. the year it entered service

- The carrying capacity of the device / the machine.

If the holding time is less than five minutes when a power failure occurs, a warning notice on the device is mandatory. In such cases, loads must not be raised above a height of 1.8 metres. A corresponding warning notice then needs to be in place.

Point 7.2.3. of EU standard EN 13155 recommends the fitting of the following additional plates:

- Never stand under a suspended load.

(advise of the danger of loads dropping) - Only use lifting tackle for appropriate loads

- Prohibition for use on construction sites if equipment was not designed for that form of use

- Read the operating manual before using the device

The consequence

If officially required things are not present on the vacuum lifting device, then the vacuum lifting device is not safe to operate, even if it is OK in technical terms. These things should therefore all be checked and corresponding notes should be made in the maintenance log. Work cannot commence with the device until all of this has been done.

All of this is simply to ensure that, as the party responsible for workplace safety, you have done everything necessary. After all, that should be the objective of conscientious maintenance.