The carrying capacity of a vacuum lifting device depends not only on the carrying capacity of the suction cups but also especially on the size of the carrying frame.

The maximum projecting end of the material to be lifted is very difficult to define and depends on many factors. The stiffness of the material is very important. In relation to this question – generally the horizontal application is always the more critical consideration. If the material projects too far and does not have sufficient stability, it will camber.

Experiment:

Hold a pencil horizontally, take a 20 x 30 cm sheet of paper and center it over the pencil. What does your paper do? Is it straight or does it hang down?

A sheet of paper placed over a pencil.

Now take two pencils and hold them at a distance of approx. 1 cm and now centre the paper over the two pencils. What does your paper do?

A sheet of paper placed over two pencils placed close to one another.

You can go on with this experiment by positioning the pencils further and further apart.

A sheet of paper placed over two pencils placed far apart from one another.

The result will be: the further apart, the less bending of the ends of the sheet – until the point you will now need a support.

A sheet of paper placed over two pencils placed at opposite ends of that sheet.

This experiment is a very good demonstration of the horizontal transport. Can you now imagine how strong the outer suction cups are stressed because of the bending? And not only the bending but also the force from the corresponding lever arm make it impossible for the outer suction cup to hold the load. Therefore, the frame with the suction cups must nearly reach the size of the transport load. Bending of the materials specifically results in disconnection of the suction cup.

With a 1-circuit vacuum system it is so that, if one suction cup is overstressed, a leak occurs in the vacuum system and all suction cups will release within a very short time. This loss of vacuum can no longer be compensated.

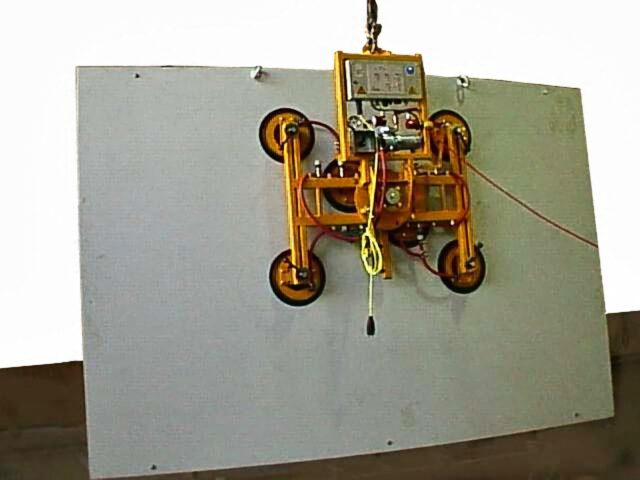

When taking into consideration the accumulator device Kombi 7011-DS it means, that:

The suction cups 388 used by us can hold onto a clean glass sheet until they detach, according to the type of force effect and speed, approx. 300 kg at a negative pressure of 0.6 bar, without consideration of a safety factor. In theory, a 7011-DS with 6 suction cups could hold approx. 1800 kg horizontally (without a safety factor).

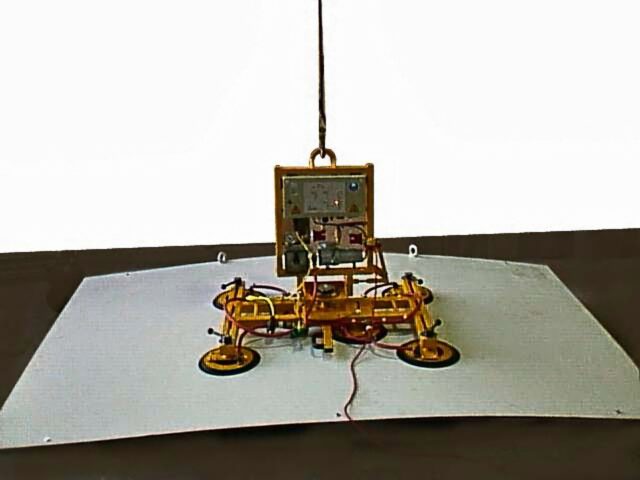

The frame dimensions are approx. 1.0 x 0.8 m. According to our specifications it is possible to move materials up a maximum dimension of 2.0 x 1.8 m.

Take for example a steel plate with the dimensions 3.0 x 2.0 m and a weight of approx. 580 kg and you want to move it horizontally.

It would take about 10 seconds before the plate would fall down.

(horizontal load scenario)

If you strengthen the steel plate with supports, the transport is possible, provided that you take care that no bending occurs.

During the vertical use the stiffness is not as important because each plate material has a certain inherent stability in this direction. Pick the sheet of paper up with two fingers on one corner and hold it vertically so that the side with the 30 cm is horizontal and the 20 cm side vertical. The sheet will is suspended relatively straight without bending.

If the inherent stability is too low, the bending of the material can lead to the same effect as in the horizontal application.

When taking into consideration the accumulator device Kombi 7011-DS it means, that:

The suction cups 388 used by us can hold onto a clean glass sheet until they pull-off, according to the type of force and speed, approx. 200 kg at a partial vacuum of 0.6 bar without taking into consideration a safety factor. In theory, with a 7011-DS with 6 suction cups, one could hold approx. 1200 kg vertically (without a safety factor).

The frame dimensions are approx. 1.0 x 0.8 m. According to our specifications it is possible to move materials up a maximum dimension of 2.0 x 1.8 m.

Take for example a steel plate with the dimensions 3.0 x 2.0 m and a weight of approx. 580 kg and you want to move it vertically.

(vertical load scenario)

In fact the steel plate can be held but the bending of the steel plate can already be recognized clearly. We have now reached the limit.

Another factor is of greater importance. This is the lever arm effect, caused by not centring the suctioned load. Forces greater than presumed can affect the suction cup, an additional stress occurs via the displacement of the centre of gravity of the load in relation to the suspension point. This can also lead to an overstressing of the suction cup.

Experiment:

For demonstration of the influence of the force caused by the lever arm effect, take a hammer (about 250 g in weight), hold the end of the handle with your thumb and forefinger so that the steel part hangs down vertically.

This is the example of when the load center corresponds with the suspension point i. e. the load is sucked on centrically.

Now try to hold the handle horizontally so that the iron part faces horizontally to one side. Do not forget to hold the hammer only with your thumb and forefinger.

Do you now understand the influence of the lever arm effect on the suction cup? The force you now have to use is many times higher than before.

If the transport load is to be turned vertically, it is very important that the transport material is sucked on at the centre of gravity. Otherwise, it could be that the force of the corresponding lever arm effect could have a negative impact – and all the calculated safety factors would be exceeded very quickly.

The larger the frame the easier the frame can be positioned on the transport load. Take a stamp and try to center it with the naked eye on the sheet of paper (20 x 30 cm).

Repeat it with a paper sized 10 x 15 cm. You will find out that it is much easier to centre the 10 x 15 cm paper on the large sheet (20 x 30 cm) than the stamp.

Which do you find easier?

We hope that these explanations help you to clarify the significance of the relationship of the carrying frame size to the size of the transport load.