What is important to know?

The machinery directive states that all machines and devices made available to employees must have a CE mark and a conformity declaration. This is the only way for the employer to ensure that everything has been done correctly. In the event of a workplace accident, this should assure that the insurance company will provide cover, and should remove the risk of any legal action.

However, it is not sufficient to place all your trust solely in a CE mark. The business owner should go one step further to ensure that every base is really covered. If there are any grey areas, every insurance company will try to get the businessman to contribute to costs, if not actually to pay them in full.

With this in mind, we would like to provide you with a couple of prompts that every businessman would do well to consider. Or you should at least take this into account in your considerations. After all, everyone knows the motto: Ignorance is not a legal defence.

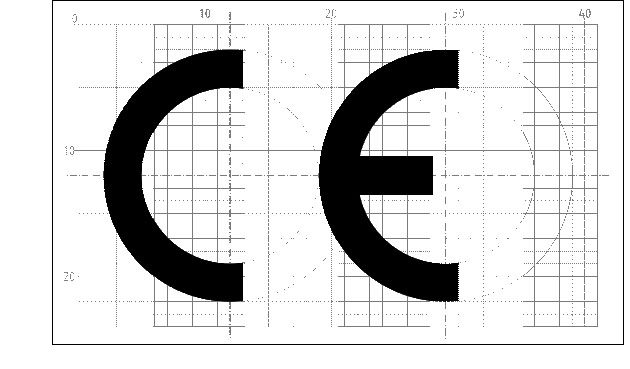

1. Ensure that the correct CE mark is attached

Anything else is not a CE mark.

2. The conformity declaration is absolutely essential

The machinery directive stipulates that both of these belong together. It states:

that without a CE mark, no conformity declaration is valid.

In accordance with the machinery directive, no CE mark can be applied in the absence of a conformity declaration.

3. Who can issue a conformity declaration?

Only the European manufacturer or the importer who imports the device into the EU. The address must be a European one that can be visited. A company from China or the USA cannot issue a valid conformity declaration in accordance with the machinery directive.

So you should take a look at the conformity declaration to avoid any unpleasant surprises. I would not pay for the device until everything is found to be good.

The person who issues the conformity declaration is responsible for the accuracy of the statements made.

Without a valid conformity declaration, it is not right to assume that the workplace equipment provides sufficient safety for the user.

4. What should feature in the conformity declaration?

The conformity declaration should indicate the status of machinery directive to which it refers. For example: in accordance with EC Machinery Directive 2006/42/EC, Annex II A

Apart from that, the applicable standards should also be listed.

In this regard, EN 13155 is very important for vacuum lifters and it should always be included in the listing. In Tip 12 “Minimum requirements for a vacuum lifter”, we have once again set out what that means in detail.

For someone who wishes to move individual panes of glass using vacuum technology, compliance with EN 13035 Parts 1 and 2 is important. Especially if other lifting systems such as cranes are also being used. Or if so-called glass robots are in operation. This is because in normal cases, EN 13155 is only intended for ‘loose lifting equipment’. With EN 13035 Parts 1 and 2, this standard is extended to include the transport of single glazing units on devices of this kind.

5. What else needs to be taken into account?

The conformity declaration requires a correspondingly comprehensive operating manual to exist in the relevant national language. Without an appropriate set of operating instructions in the relevant national language, the device is considered not to have been supplied in full, and fails to comply with the conformity declaration.

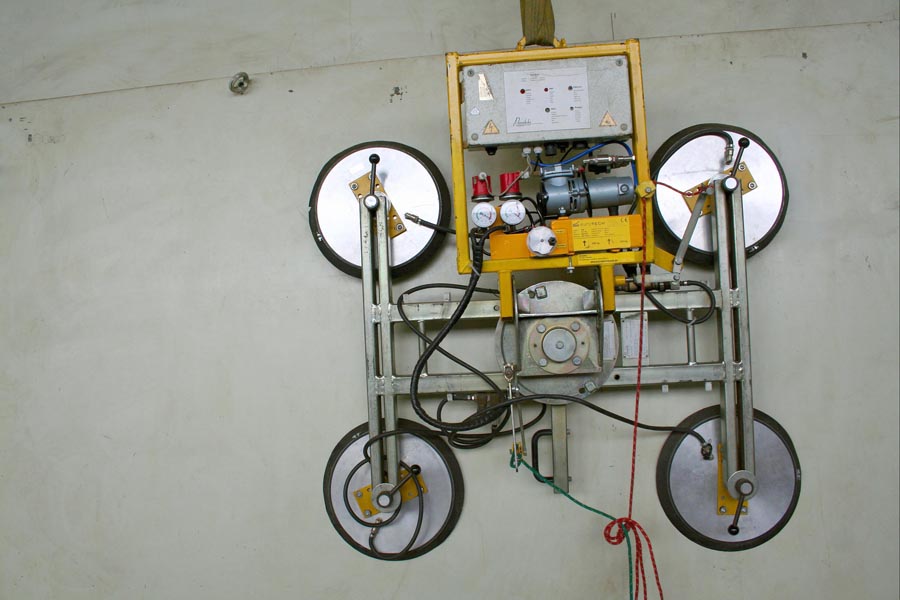

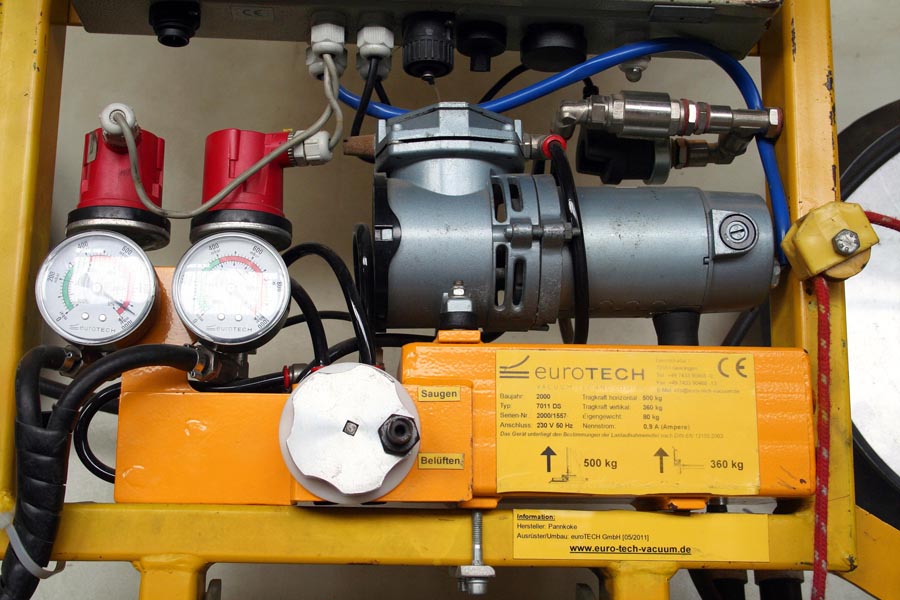

The device must have a type plate on which the manufacturer / importer and their complete address is displayed. Furthermore, important technical data must also be provided.

You should therefore be able to find these details on the type plate of an item of ‘loose lifting equipment’:

- Company name and address

- Designation of the device

- Serial number

- Dead weight

- Year of construction

- Carrying capacity

How is it with the purchase of second-hand devices?

Here do, what is written above still applies and, in addition, you need to watch out for modifications. If the device is no longer in its original condition, it has been modified. If a modification has been made with technical safety implications, the conformity declaration and the attached CE mark cease to be valid. The party that modifies technical safety aspects of the device then becomes ‘the manufacturer’.

The important thing here is that the operating instructions must be in the relevant national language. Maybe we should take a real-life example. Let us suppose that the manufacturer originally sold the device to Denmark, accompanied by a set of operating instructions in Danish. He therefore did everything correctly. If the original customer now sells that device to a buyer in France, the original customer is then obliged to obtain a set of operating instructions in French. The manufacturer is not obliged to supply this French manual. In some cases, this can give rise to costs previously not anticipated.

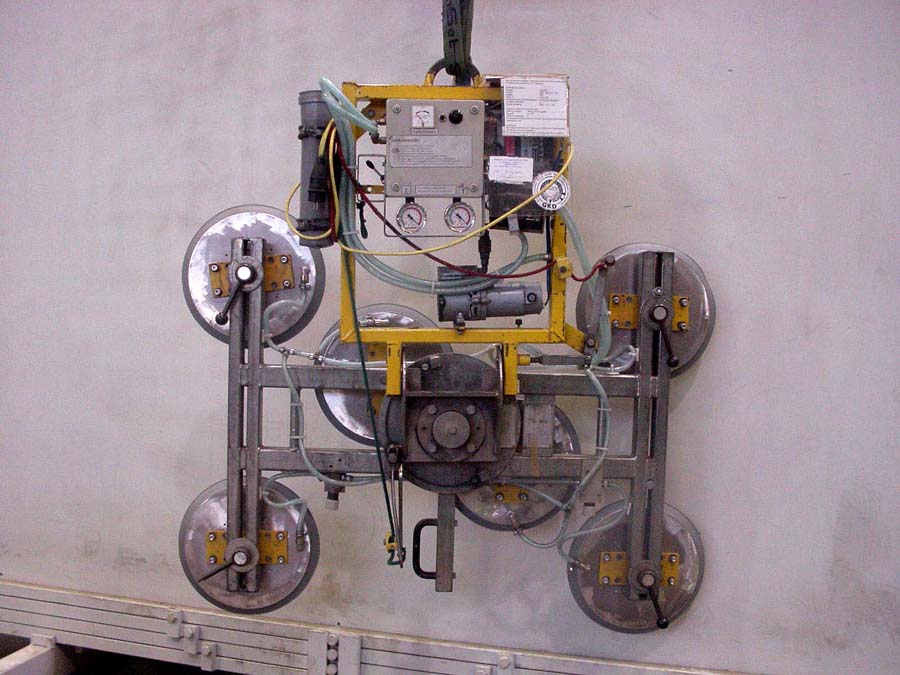

Quite a few things are not immediately obvious to the uninitiated. Replacement of the suction cups constitutes a modification to the vacuum lifter with technical safety implications. You see, suction cups, although based on a similar design, can differ substantially in terms of lifting capacity. To avoid stepping into a trap, you should always use suction cups made by the original manufacturer.

On our YouTube channel, you can view various lifting tests conducted with different suction cups to illustrate this point. These differences can vary by as much as 25%. If the original is able to support a vertical load weighing 200 kg, and its successor is only able to lift 150 kg, that has serious implications for the safety of the vacuum lifter. You should always bear this in mind.

If you wish to purchase a second-hand vacuum lifter, you should always watch out for the age of the suction cups. We, as well as Woods, recommend that you replace the suction cups every 24 months to assure sufficient lifting capacity.

Pay attention to changes on the load-bearing parts. In can be assumed that retrospectively welded lifting eyes or similar items were not attached by the manufacturer. Cracks in the welded seams point to pre-existing damage.

If you pay attention to all of this, it may well make good financial sense to purchase a second-hand vacuum lifter. However, if you fail to do so, it can be a very costly proposition to restore one of these vacuum lifters to its proper operating condition.

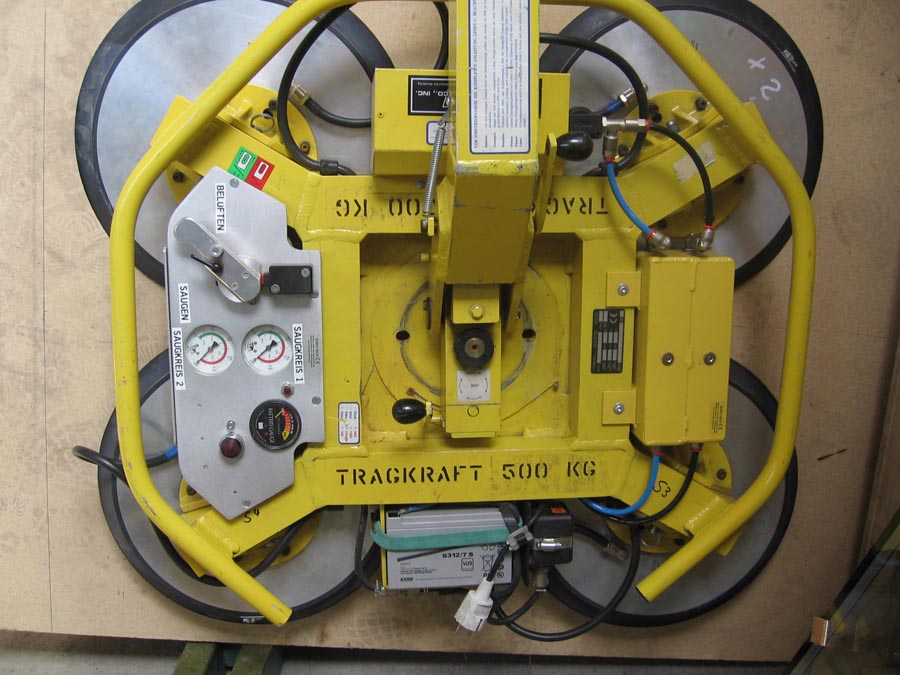

A pitfall to watch out for – modified devices

There are still many single-circuit vacuum lifters that have been converted into 2-circuit vacuum lifter by one company or another. Exercise particular caution with devices of this kind. You see, in all probability, this modification will have technical safety implications. In such cases, the original manufacturer of the single-circuit vacuum lifter is no longer responsible for the device, and is no longer considered to be the manufacturer of it at all. Instead, the party that modified the device becomes the manufacturer of the device and, after conversion work, introduces it to the market as a new product. That party is obliged to remove the old type plate and to replace it with a new one. Furthermore, he must also supply an operating manual and an EU conformity declaration for the “newly created device”, and this must be in the national language of the user to whom the device was sold.

If you wish to have an inspection or maintenance carried out by the original manufacturer, we would normally refuse to meet that request. You should bear all of this in mind before proceeding with a purchase of this kind.

Here are a few examples from real life to illustrate how careful you should be.

DIY constructions – you should bear this in mind

Often, when carrying out maintenance work, we have come across DIY constructions. If you do something like that for your own use, please always bear in mind that you also need to obtain a conformity declaration, a type plate, a CE mark and an operating manual for your device. Many are not aware of this, or they choose to ignore it. However, that is what is stipulated in the machinery directive, and it should be taken into account. If not, the person responsible will find himself in a lot of trouble if he provides this to his employees, and if an accident then occurs. It is much better to prevent this from happening in the first place.

We hope that these instructions provide you with a useful guide, one that prevents you from investing your hard-earned money to no effect.