Compound-Pump

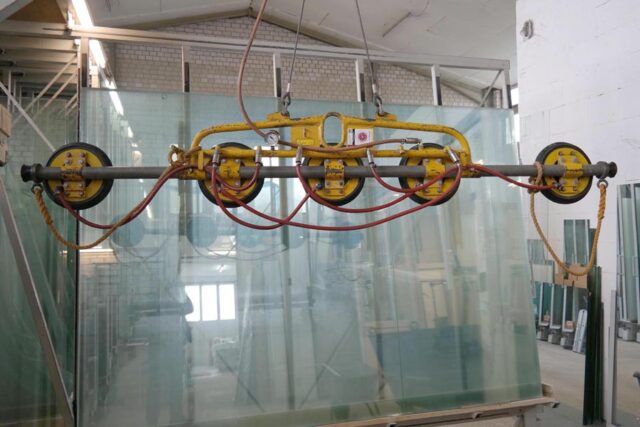

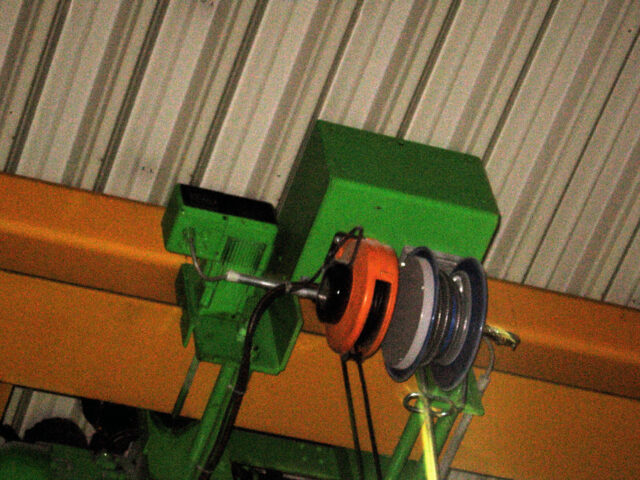

In your glass store, are you still using a vacuum pump on the crane line that supplies vacuum to the suction cup support frame via a hose reel?

If so, you should consider the risk that this entails. Even though this kind of application may have been in operation on your premises for many years, and even if you have never encountered any problems, there is a high risk of extremely serious injuries. This is not just a theoretical possibility: there have already been actual cases. The worst case known to us caused an employee being on sick leave for 9 months. A shard of glass cut open his shoulder area, severing sinews and tendons. Therefore, after conducting your risk assessment, if you still use a hose reel, you should have it inspected thoroughly at least once a month. If a serious accident like this happens on your premises, you can then at least provide evidence that you had identified this weakness and were conducting regular checks. That is a better policy than an “out of sight, out of mind” approach to a hazard known to you.

Weak point in relation to the hose reel

The greatest weaknesses of a hose reel are its axial rotation and its seal integrity. Anyone who believes that a leak extends right across the entire area would be entirely wrong. Leaks usually only affect a small part, but this can have the same impact as the hose getting severed and vacuum getting lost totally and suddenly. I hardly need to tell you in any detail what that signifies. Under certain circumstances, this small section may account for less than 1 cm of the entire hose. Beforehand and afterwards, everything is OK, but if you are transporting the pane of glass at precisely this height, then the pane drops and you have no opportunity to react in time. That is precisely what makes this so dangerous.

However, how can a hose reel of this kind be inspected or tested?

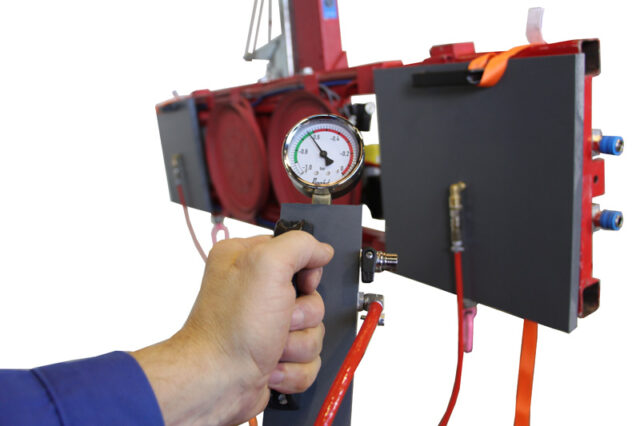

Like almost anything, this is very easy, provided that you know how to do it. You need a few metres of hose with a control vacuum meter. At the other end is the mating piece for the coupling on the hose reel. It would be of benefit to have a bleed valve to check the warning signal. Then the hose would get reeled and unreeled very very slowly, while watching the vacuum meter throughout this process. If the vacuum drops, but only at one location, the seals or even the entire hose reel should be replaced straightaway. A very important aspect of this test is the very slow pace of movement. Otherwise, the defective area may get jumped over, and you may not detect the fault.

Our test kit is able to test more than just the hose reel: it can also test the warning signal and, with an accumulator vacuum lifter or on devices with disengagement capability, can also test 2-point control if a suction cup test plate is available.

To test the hose reel you can hold the vacuum meter comfortably in one and while you move the hose up and down slowly with the other hand.

And what else speaks against continuing to use this solution?

According to EU standard EN 13155, ever since 1 January 2004, every vacuum lifter should have a control vacuum meter with a designated danger area and operating range. Also, there should be a visual or acoustic warning device.

Many tend to say “I have what I call legacy stock protection for my old devices”. However, with regret, we must contradict this, since the workplace safety directive dated 1 June 2015 abolished once and for all this type of protection for legacy equipment. Instead, it requires that all equipment must be brought up to state-of-the-art standards. And that state-of-the-art techncial status is also defined in applicable standards, ensuring that the circuit closes again. “That’s no big deal” you may say, but when an accident as serious as the one described above happens, any insurance company is going to try and avoid shouldering the costs. Even worse if the company boss or safety officer or anyone else responsible is found guilty of negligence. With this in mind, you should review your risk assessment for a solution of this kind, and consider the potential ramifications of not acting on it. As the phrase goes, “Ignorance is not a legal defence”.

Accordingly, every one of these solutions should involve having an appropriate warning device. Please note though that this warning system must also function in the event of a power failure.

Back in 2004 we decided that there really was no good answer to this problem for a vacuum pump on the crane line, so we stopped pursuing this concept. Not only that, but the issue with the hose reel is not resolved either, and in our estimation the potential danger is too great. At least while accidents of this kind can still occur.

Our advice

- Convert your range of equipment.

- On the crane hook, only use complete vacuum lifters.

- Stop using long vacuum hose lines.

And until you have implemented the above, keep checking your hose reel. Whether you use our test kit for that or something you have manufactured in-house, you should be diligent when conducting these tests. Your personal safety and that of our payroll staff is at stake!

To prevent disaster from striking, give careful thought to why you are still using equipment in this way. Keep a written record of your considerations. We most certainly advise you against a policy of ”if it ain’t broke, don’t fix it”. In our view, the solution with separate vacuum generation, a connecting hose and a support frame with suction cups is much too dangerous to continue being used.