we are Pannkoke

We, Pannkoke, are a specialist company that manufactures equipment, machines and tools for the glass processing industry. Our mid-sized enterprise was founded in 1900.

Since 1956, we have been developing and producing practical vacuum lifting devices.

Our many years of experience means we can react flexibly to the wishes and requirements of our customers. Solutions tailored to resolve customer problems are our strength.

Quality and service come first. During construction, special importance is placed on assuring the long, useful life of the devices and machinery. When selecting suppliers, we insist on high quality and long-term availability.

The oldest vacuum lifting devices that we maintain yearly and which are still in full operation originate from the year 1965.

2016

It looks enormous – a bent area of 6 x 2 m

SGGS Döring, a Berlin-based company received a special vacuum lifting device that would easily handle a pane of glass that was curved 6 m longitudinally in both the convex and concave planes and with a weight of up to 1400 kg. We received a large order for several vacuum lifting devices which can lift up to 1700 kg from Hevron in Switzerland.

2014

There are also solutions for special requirements.

Lindner in Manchester requires a particularly flat vacuum lifting device to move bent glass walls for a special construction. We were also able to develop and manufacture this vacuum lifting device.

2012

The compact device with 4-circuit technology

The 7411-DS7 vacuum lifting device is presented for the first time at glasstec 2012. Finally, a small vacuum lifting device which is able to lift up to 750 kg at EC construction sites with its four extensions. Ulrich Wulf leaves the company due to age reasons. We thank him for the decades of loyal and committed cooperation.

2010

The age of 4-circuit technology begins

The first Kombi DS3 with 4-circuit technology is presented at Glasstec 2010. It is exactly the right product for the Swiss company Ruch and will be acquired by them directly from the fair. Jörg-Joachim Jacobs leaves the company for personal reasons. We thank him for the decades of loyal and committed cooperation.

2006

The glass size is also growing in Germany

The first vacuum lifting devices for production of glass lengths up to 12 metres were shipped in Germany. In 2006, the first almost 9 m long pane of insulating glass was installed using a Pannkoke vacuum lifting device in the Jewellery Museum in Pforzheim under wintry conditions. Decades before, like for the construction of the jewellery museum which took place at that time, large panes were positioned using two Pannkoke vacuum lifters.

2004

The best options for building site glazing

Glasstec 2004 sees the launch of the 2 circuits vacuum lifting device 7211-DS3. This is the first vacuum lifting device in the world that can turn and swivel 1000 kg on an EC construction site. It also complies with the requirements of the new safety standard EN 13155.

2000

100 years Pannkoke

There was an exhibition of Pannkoke tools and vacuum lifting devices from the past 100 years at the glasstec 2000. The trade fair was also the venue for the launch of the first 2 circuits vacuum lifting devices compliant with the latest safety requirements. During its many years of experience, Pannkoke has distinguished itself as a leader in fulfilling extraordinary customer wishes and requirements in respect to vacuum lifting device needs. Quality and service always come first. Already during construction, special attention is given to promoting the long life of the products. The name of Pannkoke therefore stands for the highest quality and customized services even into this century.

1996

Vacuum lifting device for tilting

The Asian flat glass industry ordered several vacuum lifting devices for tilting. The largest devices were designed for a glass size of 12 x 3m and a thickness of 25 mm.

1994

A gigantic shop windowpane

In 1994, Pannkoke constructed a vacuum lifting device for the installation of a shop window for a Japanese customer. This gigantic pane is 12 x 3 m, has a glass thickness of 22 mm and a weight of 2,000 kg. This application was so unique that it was shown in every Japanese news programme.

1993

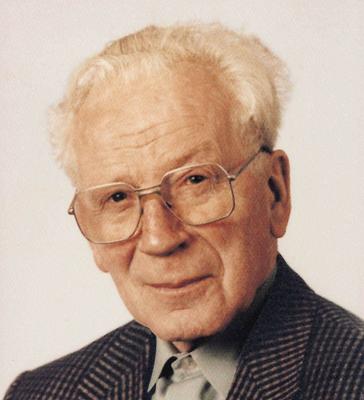

Karl Pannkoke

After a lifetime spent in the service of the glazier‘s trade, Karl Pannkoke, founder of the production sectors of vacuum handling and glass cutting technology, died on 5 September 1993 at the age of 81. Since the beginning of vacuum handling technology, it had been his special favourite, and not only in the glass field, but also in other production sectors where gas-tight materials were used. Through his initiative, the vacuum handling devices, originally seen as just a sideline of the cutting technique, came to be one of the more important Pannkoke products.

1991

Collaboration with Kiel University of Applied Science started.

Vacuum handling technology is a special challenge for son Bernd just as it had been for his father. He has his own ideas and experience and he works out a new modular system for the vacuum handling technology. In 1991, he is appointed managing director.

1990

The transition

Following the reunification of Germany, everyone is focussed on further German unity. Even in the early years of unity, Pannkoke sets us marketing stations in Dessau and Dresden. The new generation of NC cutting machines is presented at the GlasTEC ’90. The operating software with the cutting plan editor is developed by Hanic, Gelsenkirchen.

1988

The son joins in too new ideas – new technology

After his electrical engineering studies in Luebeck, Bernd Pannkoke acquires further practical experience at Siemens in Munich. In 1988, he also joins the management of the company and takes over the technical department. The new generation of vacuum lifting devices for hall construction comes onto the market in 1988. With this type of device, it is possible to install insulating panels up to a length of 12 m. A battery-operated vacuum lifting device is developed to transport steel plates weighing up to 5000 kg for the shipbuilding industry.

1978

A new technology arrives

Expansion and new challenges necessitate changes to the private company. The company Karl Pannkoke becomes Pannkoke Flachglastechnik GmbH. The children, Annegret and Bernd Pannkoke, and employees Holger Kramp, Ulrich Wulf and Jörg-Joachim Jacobs become partners in the company. The software company H+O of Hamburg programs the first cutting optimisation system for Pannkoke on an Olivetti P6060. The fully automatic multiple cutting-head machine NC-78 was introduced at the Glas’78. Glas Funke in Gemünd receives the first fully automated multiple cutting-head machine NC -78.

1975

75 years Pannkoke

On the occasion of the company’s 75th anniversary, Karl Pannkoke receives the silver badge of honour for his contribution to the glazier’s craft. The first 2-bridged cutting machine is produced and sold.

1960

First mobile vacuum lifting device

In the field of vacuum handling systems, the new Type JUNIOR for the construction site is introduced with a selling price of below DM 600.00. The UNIVERSAL type with separate vacuum pump is offered for the glass store. The first electric glass cutting table was used in Saarlouis, Germany.

1959

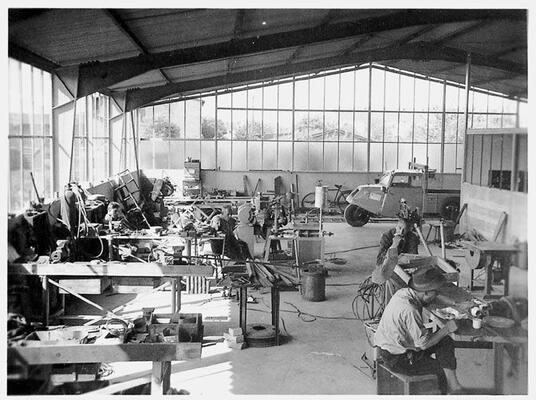

Relocation to the new production facility

In the meantime, the bunker has become much too small and the company moves to a new production location in Haendelweg in Luebeck. Development is unstoppable. The first cutting tables and glass transport racks are designed.

1958

First international trade fair

Together with the French representative, Karl Pannkoke takes part in the Paris ‘Journées Internationales de l’Equipement de Miroiterie’, organised by Saint-Gobain. It is a major success even without exhibits, because they were released by the French customs only after the fair had finished. Son Bernd is born.

1956

Vacuum handling systems conquer the glazier’s world

With the production of the first vacuum lifting device, the cornerstone of a future-oriented production field is laid in 1956. This first vacuum lifting device is sold to a glaziers’ wholesaler in Gütersloh.

1953

Development and customised inventions lead to an upturn.

Due to his technically-oriented education, Karl Pannkoke is not satisfied with the production of only tools and glazier items. Like his father, he starts to convert his practical ideas into new products. The hand grinder, radius cutter, glass drilling stand, and brass mill are only a few of his progressive developments. At Glazier Conventions, he introduces his new machinery, talks shop with customers and obtains many of his ideas for further products.

1950- 1952

First presentation of the products

At the 1st German Glazier Convention in Goslar, the new machinery is presented. The first company car, a DKW from 1936 with wooden chassis, is loaded up to travel from Glazier Convention to Glazier Convention to present the new machinery, to chat with customers and to pick up new ideas for further developments.

1949

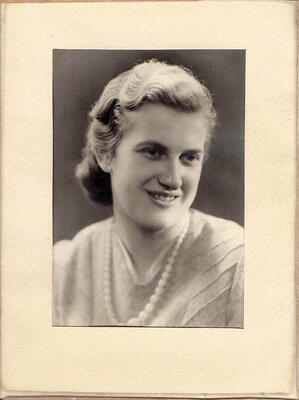

Karl Pannkoke & Margarete Ostwald

In 1949, Karl Pannkoke marries Margarete Ostwald. Margarete comes from an old established glazier family. Her grandfather was already a customer of the young entrepreneur Wilhelm Pannkoke. She herself had served a glazier apprenticeship and was familiar with the technicalities of the subject. From the beginning, Margarete takes over the business side of the company and contributes tirelessly to the success of the new company.

1945-1948

A new beginning

At the end of the Second World War, his son, Karl Pannkoke, decides to start again in Luebeck, his father’s home town. Juggling with ration coupons of every kind, he starts work in a former air-raid bunker. Under very difficult conditions, a panel pin machine and a lead drawing machine are constructed in order to stimulate the production of panel pins and glazier‘s lead. The manufacture of simple tools completes the product range.

1941

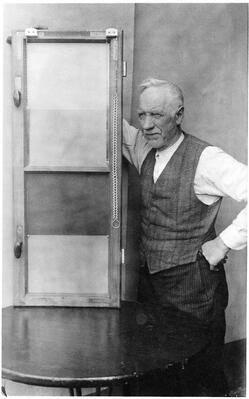

Wilhelm Pannkoke

One of the last inventions of Wilhelm Pannkoke is the glass blind for ventilation. He dies in 1941 in Berlin.

1912-1938

Upheaval

Son Karl is born on 16 August. World War I takes its toll. Wilhelm Pannkoke is called to arms. His wife Dorothea has to run the business on her own. After the war, the product range is extended to include picture frames and a picture shop and the mail order business is started.

1905-1911

The company grows.

In 1905, he marries Dorothea Kuehl. Further inventions, such as the round and oval cutting machine and many others, follow. He registers more than 25 utility models that are used in schools for prospective glaziers. With these tools, his enterprise attains a world-wide reputation in the glazier field. American technical colleges are delighted with the cutting apparatus PANNKOKE. An American patent is granted.

1900- 1904

A business is founded

While still in Bordeaux, Wilhelm Pannkoke makes his first invention in 1900: the glass cutting apparatus, which is still sold today as the cutting slide. On the advice of the master glazier, he has his brilliant tool patented, takes production and sales into his own hands and founds his business for glazier tools and accessories in Berlin at the end of 1900.

1892-1899

Years of travel

After completing his apprenticeship, he leaves Luebeck and travels for eight years as a journeyman around Europe. During his travels he goes to Hamburg, Goettingen and Dresden in Germany, and then on to Budapest, Hungary and around the south of France.

1888

Apprentice years

The 15-year-old boy serves his glazier apprenticeship under glazier master Theodor Schroeder in Luebeck.

1873

Wilhelm Pannkoke

On 18 November 1873, the company founder, Wilhelm Pannkoke, is born in Luebeck, Germany, son of master carpenter Heinrich Pannkoke.

Get in touch with our Team

Nunc eu varius nulla, at dictum nulla. Phasellus nunc enim, finibus at leo non, porta dignissim ligula. Praesent ac finibus mauris. Proin gravida, nulla ut porta commodo.

Error: Contact form not found.

Do you have any queries about our products and services? We’d be delighted if you got in touch without obligation. We are happy to help you!

your perfect vacuum lifter from Pannkoke

Initial Consultation

We carry out a free initial consultation to work out what you are looking for.Planning

We compile all the necessary information required for your project.Design

We design a vacuum lifter completely in line with your requirements and specifications.Production

Our specialist staff manufacture the planned lifting device with exceptional attention to detail and precision.Shipment

We deliver your quality-assured vacuum lifter at a time that suits you.

At Pannkoke Flachglastechnik GmbH, we manufacture specialised equipment, machines and tools for the glass processing industry.

Address

Pannkoke Flachglastechnik GmbH

Haendelweg 5, 23556 Luebeck, Germany